DC electronic loads are indispensable for testing a

variety of DC power sources. There are a number of situations that call for

testing DC power sources at low voltage, even right down to zero volts. Often

this is also at relatively high current of many tens of amps or greater. Some examples

include:

- Low output voltage power supplies and DC/DC converters (mostly for digital circuit power)

- Solar cell I-V testing, down to zero volts

- Fuel cell testing

- Single cell battery testing

- Power supply true output short-circuit testing, down to zero volts

It becomes challenging for the test engineer to find

adequate DC electronic loads for low voltage operation, especially at high

currents. Many DC electronic loads, including the ones Agilent Technologies

provides, use multiple power FETs for their input loading element. While a

power FET can actually operate down to zero volts, this is at zero current as

well. At high current a few volts is typically needed for stable, dynamic

operation at full current. As one

example Figure 1 depicts the input I-V characteristics of an Agilent N3304A DC

electronic load.

Figure 1: Agilent N3304A DC electronic load input I-V

characteristics

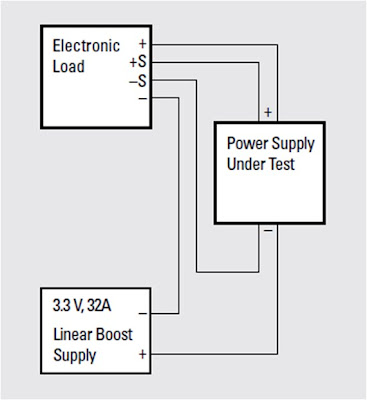

An effective solution for low voltage electronic load

operation, right down to zero volts, for the electronic load’s full rated

current, is to connect a low voltage boost power supply in series with the

electronic load’s input. An example of this set up is depicted in Figure 2.

Figure 2: Zero volt DC electronic load set up

The electronic load now sees the sum of the boost supply’s

and DUT’s voltages. Selecting a boost supply having adequate voltage will

assure the electronic load will be able to operate at full performance at full

current, even when the voltage at the DUT is zero. There are a few things that

need to be paid attention to:

- The electronic load needs to dissipate the total power of both the boost supply and DUT

- The DUT needs to be adequately safeguarded against reverse polarity if the electronic load is inadvertently turned on too hard

- The electronic load’s voltage sensing must be able to accommodate the extra voltage difference between the electronic load and DUT, due to the boost supply voltage

- The boost supply ripple and noise (PARD) can contribute to noise measurements made on the DUT