I wanted to talk about a feature in our Advanced Power Supply family (APS from here on out) that not too many people know about. The APS features two user defined statuses in the Operation Status group. Here is a rundown of all the entries in the group:

You can see that bits 7 and 8 are User1 and User2.

Using the advanced triggering system for the APS you can define what conditions will trigger a change in these two statuses. The N7906A Power Assistant Software (download link) has a very handy graphical way to set up the trigger. As an example, let's say that I wanted to change the user defined status when the voltage exceeds 1 V and the unit goes into positive current limit status. Using the Power Assistant Software I would whip up the following:

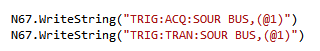

After I draw out my trigger expression, I can either download it to my APS or I can click the "SCPI to Clipboard" button on the top of the page. If I hit that button now and then hit paste here, I get:

:SENSe:THReshold1:FUNCtion VOLTage

:SENSe:THReshold1:VOLTage 1

:SENSe:THReshold1:OPERation GT

:SYSTem:SIGNal:DEFine EXPRession1,"Thr1 AND CL+"

:STATus:OPERation:USER1:SOURce EXPRession1

I can just copy this code into my program. It's a pretty convenient.

I think the big question is: What can you do with this? The answer is: whatever you want. It's user defined so you can use it in whatever way you see fit. If you want to check if the current exceeds a certain threshold you don't want to do a bunch of measure commands in loop, you can define that as your trigger and then just check the Operation Status Group (using the STAT:OPER? or STAT:OPER:COND? queries).

I think that the most powerful thing that you can do with this is set up a SRQ handler to act when the user statuses change. This is actually a project that I am working on presently so I have not implemented this just yet (but I will in the near future). When I do, I will definitely write a blog post about it though! I wanted to get the word out about this because even I did not automatically think about this when faced with a issue that just screamed to use this.

Thanks for reading and stay tuned for a future installment on this topic!

.JPG)